Our first 5 new Fuel it connected sensors have just arrived …. What’s the change, you might ask? Well, our sensors have just moved to a new stage of development. They are machined, we will explain this process. Our previous sensors were made in 3D printing but this did not allow for optimal quality. In machining, this changes everything and you will see it for yourself. Enjoy your reading :)

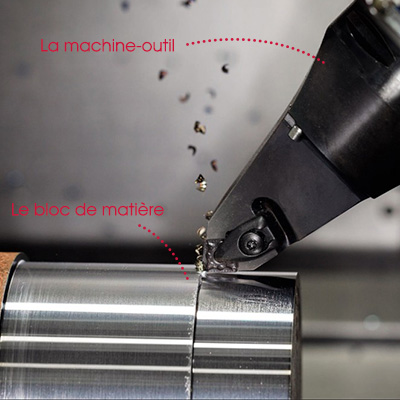

What is machining?

The basic principle of machining is material removal. It is obtained by cutting the material of the part (in our case, a plastic block). Cutting is done by moving a tool in contact with the part, put in strong rotation, to obtain the desired dimensions, using a machine tool. With this technique, we obtain parts of great precision.

In general, the shapes of the machined surfaces can be flat or of revolution. The main machining operations are milling (flat surfaces) and turning (surfaces of revolution). For our sensor, it is of course the shooting that was performed.

Machining can be applied to many materials such as: steel, aluminum, brass, stainless steel, titanium, plastic and many other materials.

Our sensor made in 3D printing

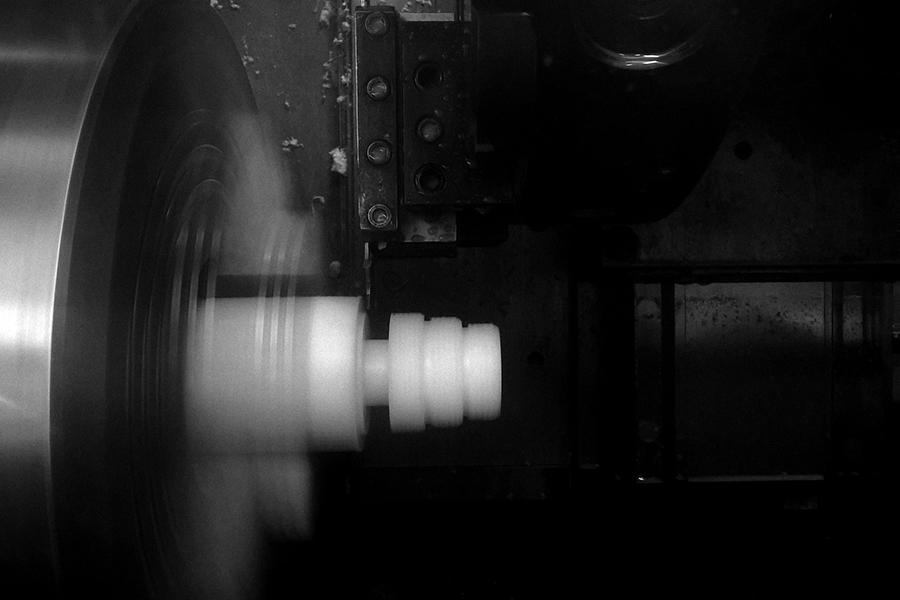

Our machined sensor

(With the machining technique engraving is not possible, so the logo does not appear!)

A change of the screw pitch as well

Sensor in 3D printing

Sensor in machining

The video of our machined sensor

Conclusion

As you could see, our sensors have strongly evolved in quality!!! And we are more than satisfied! Our next step? Make it 100. and even more with your support.

We hope this news warms your heart,

Stay warm!

The Fuel it team :)